Introduction of sheet cutting

Sheet cutting methods

The method of cutting sheets of steel is different and not the same. You should know that these steel sheets in the black paper industry are the main raw material in the parent industry, which are transported in a coil to the factory and cut from there to the desired dimensions, and finally produce the desired shapes.

It should be noted that various factors are involved in choosing the type and method of cutting, which can be the cutting speed, sheet thickness, final costs, as well as the quality and standard included in the cutting lines. As mentioned, cutting methods are different from each other. In the following, we have examined new types of cutting methods for CNC iron sheets. Join us.

Criteria for selecting the most suitable sheet cutting method

Automatic cutting of sheets is done using a strip consisting of gas, rays or water, and this is done by applying force to the surface of the sheet. There are various criteria for cutting quality, such as sheet thickness, accuracy and quality, as well as the conditions and tools used. You should know that the thickness criterion is important in that the amount of resistance that the sheet has against cutting is directly related to its thickness.

Sheet thickness

The thickness criterion in choosing how to cut is as follows:

1) If the thickness of the sheet is less than 2 mm, the most appropriate method of cutting is the use of laser.

2) If the thickness of the sheet is less than 3 mm, the most appropriate cutting method is the use of laser and plasma.

3) If the thickness of the sheet is less than 6 mm, the most appropriate method of cutting is laser, plasma and waterjet.

4) If the thickness of the sheet is more than 200 mm, the most appropriate cutting method is to use air gas.

5) If the thickness of the sheet is more than 50 mm, the most appropriate method of cutting is to use air gas and waterjet.

6) If the thickness of the sheet is more than 31.75 mm, the most appropriate cutting method is to use air gas, waterjet and plasma.

Accuracy, quality and cost

The criteria of accuracy, quality and cost in choosing how to cut are as follows:

1) If the final appearance and shape of the product after cutting is important to you, we recommend that you use the waterjet method to cut the desired part instead of the methods of using plasma, laser and air gas.

2) Pay attention to the workload and final costs. You should know that the waterjet method can not cover the cutting of a large volume of product, on the other hand, the air gas method is the most suitable cutting method in terms of economy and final cost.

The importance of conditions as a criterion for choosing the cutting method

We recommend that you consider the general conditions before choosing a cutting method, so that if you need a cut that can produce less waste, use the waterjet and laser cutting method. If you need to make a one-handed cut, you can also use the laser and waterjet cutting method.

Tool

1) If you intend to cut the sheet using two or four torches, waterjet cutting method with a number of blue jet pumps is the most suitable method and plasma, air gas and laser method is not suitable.

2) You should know that laser cutting is a traditional method that has the ability to cut one head, while the fiber laser has the ability to cut several heads and completely simultaneously.

3) In sheet cutting, it will be economical to combine the two cutting methods. These combinations, which can be a combination of the waterjet and air gas methods or a combination of the waterjet and plasma methods, are such that in the beginning, the process is precise and slow, then it becomes cheap and fast.

4) It should be noted that to cut parts that are made of metal and their diameter is small, such as aluminum, they use the manual method.

5) You should know that manual method for cutting steel sheets that have low flexibility, carbon content and high thickness is not recommended at all.

New cutting methods

Among the new cutting methods, the following can be mentioned:

• Water jet Cutting

• Oxy-Fuel cutting

Laser cutting

Plasma Cutting

• Cutting the guillotine

Cutting with water jet machine or Water jet Cutting

The final lines of the sheet metal cutting machine with waterjet or in general in cutting sheets of any material are very precise and of good quality. Cutting iron sheets with water or the waterjet method is considered to be inspired by nature because the type of cutting is similar to the polishing of rocks and stones.

In this method, the sheet is cut with the help of combined water or an abrasive solution so that the cut edge lines do not have thermal deformation. The waterjet method is one of the most suitable methods for cutting metals that are sensitive to heat. Since the water flow tends to diverge, so in this method, all sheets with a thickness of 150-203 mm can be cut.

You should know that the final cost of using this method is slightly higher than other methods such as plasma. This is because in addition to the high cost of the pump used, the costs are calculated based on each hour of cutting work. In addition to the high cost of this method, it also has advantages that can be reduced water consumption and no waste left. Applications of this method include cutting rough surfaces and materials, cutting stone and hard materials such as bulletproof glass.

Oxy-Fuel cutting

This method is one of the oldest methods of cutting iron. In the air gas or oxygen method, the desired sheet is cut with the help of flammable gas and using a pump burner. This method is also known as flame cutting, which is the most suitable method for cutting carbon steel or steels that have a light and thick alloy.

This method also has many advantages, among which we can mention smooth cutting and one-layer sheets that are very thick. In this way, sheets thicker than 25 mm can be cut with the help of this method. It is interesting to know that with the help of several torches and simultaneously, the efficiency of this method can be increased. You should know that the working speed in the air-gas method is low and is equal to 508 mm per minute.

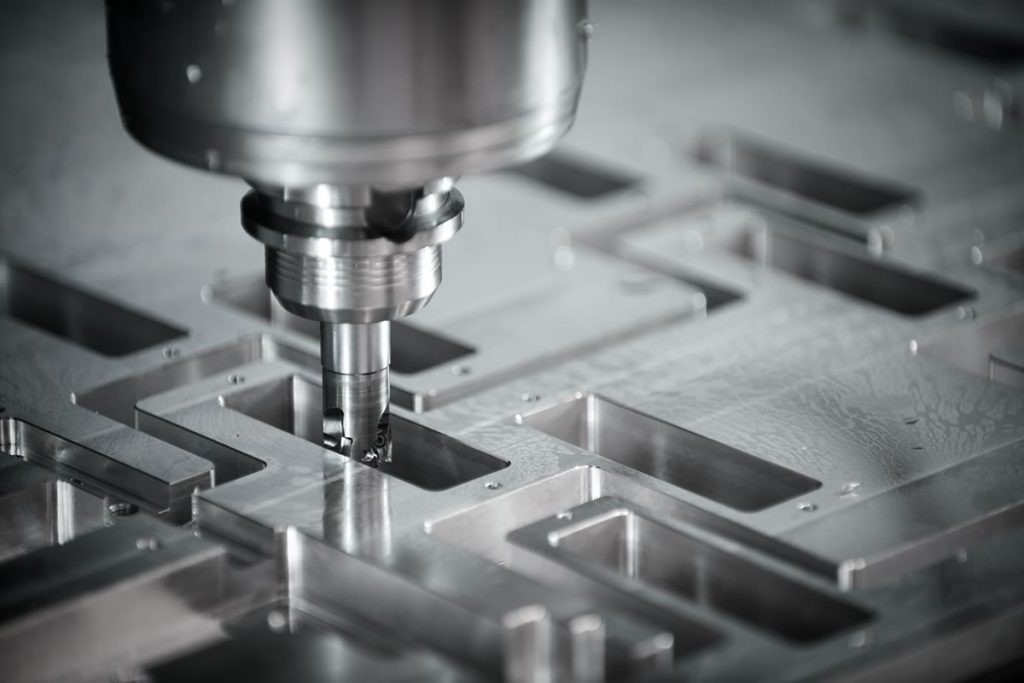

Laser cutting

Laser sheet cutting or laser cutting of iron sheets in general or laser iron sheet cutting with the help of laser sheet metal cutting machine is one of the most accurate and best methods that is used to cut thin sheets. In this method, which uses intense light rays to perform cutting operations, it has two types of fiber and carbon dioxide. Each of these methods is selected according to the type of sheet.

You should know that the carbon dioxide laser method is not applicable in cutting aluminum, copper and brass sheets. However, the fibrous method is used to cut most metals with low thickness, such as cutting steel sheets. Although laser cutting covers parts up to 31 mm thick, you should know that before cutting parts larger than 25 mm, general conditions such as beam quality, nozzle condition, gas purity, etc. should be carefully examined and appropriate. The mentioned conditions ensure that the quality of the cutting lines is in a good condition. The working speed of the laser method is low due to the limitation of the chemical reaction rate of oxygen with iron, which increases the quality and accuracy of the cuts and creates small and precise holes in the final product, so it can be said that the low speed in this method , Is one of its advantages.

Plasma Cutting

The cutting speed by the plasma method is higher than the cutting speed by the air-gas method. This method can be used to cut steel sheets. They have a small percentage of carbon. Although the speed of this method is very high, but you should know that the quality of cutting at the edges is a bit low and its electric arc system requires cooling, cable and hose connections, power supply and gas control, which increases the cost of using this method. In a way, in general, using this method is more expensive than the air-gas method.

The method of work in this method, which can be considered as a suitable alternative to the flame method, is that a set of oxygen gas, compressed air and noble comes out of the nozzle and cuts by creating heat on the surface of the desired metal. . This method has many advantages such as quality, accuracy, speed and high flexibility.

Guillotine cutting

Guillotine cutting is automatic, which is economical. The devices used in this cut are divided into three categories: pneumatic, mechanical and hydraulic.