Waterjet cutting CNC machine BFT (Austria)

.jfif)

Drive power: 11 - 75 kw and more powers

Pump power: 15 HP - 30 HP - 50 HP - 75 HP - 100 HP - 150 HP - 200 HP

Pump Pressure: Up to 12000 bar

Dimensions: All sizes upon customer request

3m * 2m , 6m * 2m and other sizes

Pictures | Sizes |

|---|---|

| 3m * 2m |

| 6m * 2m |

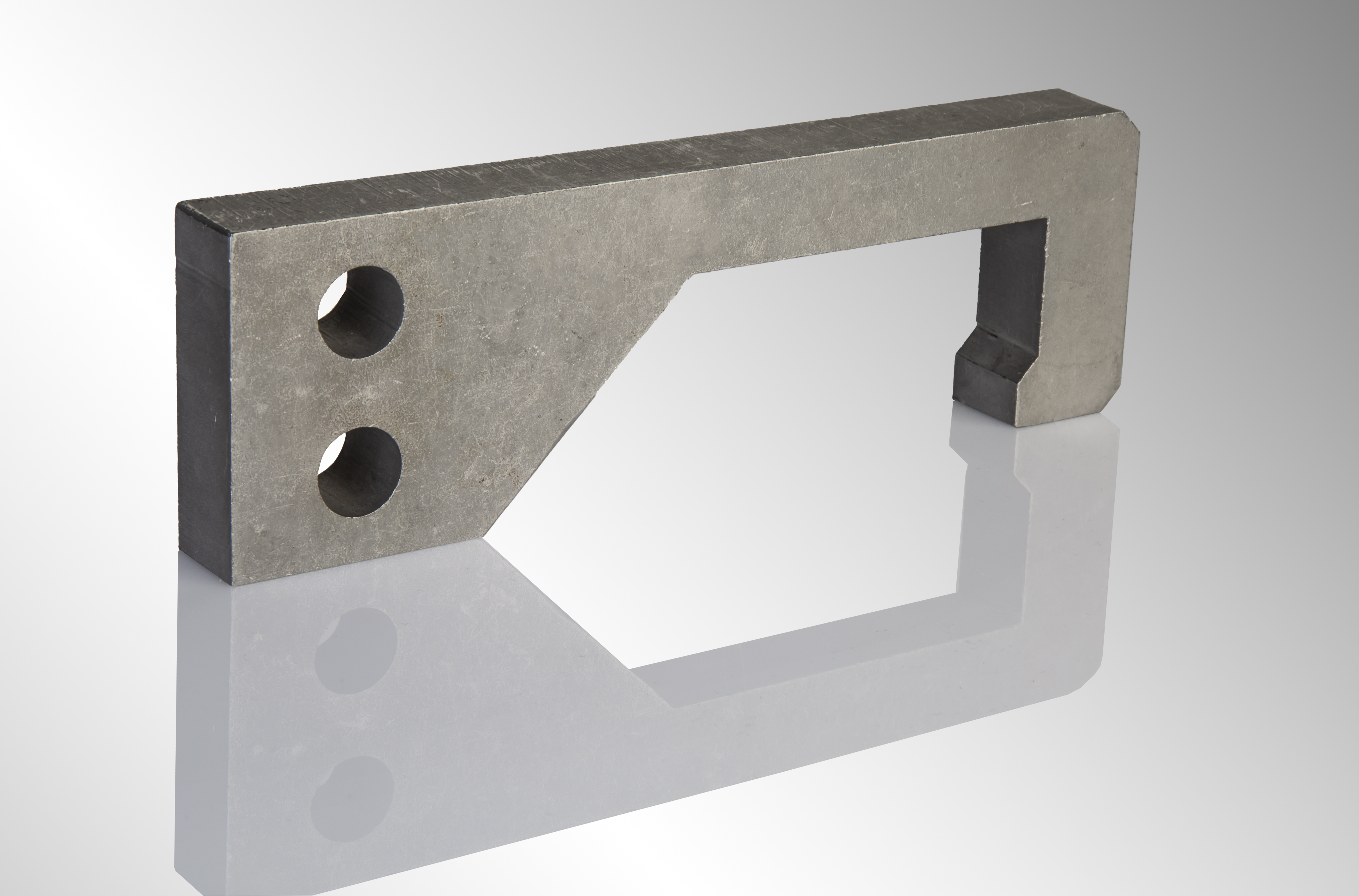

Cutting material: All materials

(Steel, super alloys, titanium, aluminum, stone, glass, rubber, etc)

Guarantee: 5 years CNC guarantee and 1 year Pump guarantee

After-sale service: 15 yeras

Applications

RADOX cutting machines can be used in wide variety of manufacturing industries such as:

1) Automotive industry

2) Aerospace & energy

3) Shipbuilding industry

4) Oil and Gas industry

5) Agricultural machinery

6) Machinery manufacturers

7) Home appliances and equipment

8) Elevators & escalators

9) Electrical panels

10) Lighting equipment

11) Heating and refrigeration industries

12) Hospital & Lab equipment

Brand, type & Description | Item | Row |

| ECOTRON/ SERVOTRON pump (BFT Austria) | Waterjet pump | 1 |

| ✓ | Linear motion guide for all axes | 2 |

| ✓ | Stainless steel water tank | 3 |

| Two servomotors in both sides of Y axis | Double drive | 4 |

| Nesting, Sheet alignment, Piercing | Software | 5 |

| Planetary zero back lash | Gearbox | 6 |

| 25000 mm/min | Max. positioning speed | 7 |

| X=2.000 mm, Y=3.000 Z=300 mm | Working area | 8 |

| ±0.15 mm | Position accuracy | 9 |

ECOTRON HIGH PRESSURE PUMP BFT (Austria)

ECOTRON® is available in the power classes 11 kW to 45 kW. The operating pressure of 4,000 bar is the perfect balance between long maintenance intervals and high cutting speed. ECOTRON® is basic model with flow rates between 1.2 and 4.3 l per minute and an operating pressure of 4,000 bar.

CONVENTIONAL WORKING PRINCIPLE WITH MANY EXTRAS

Pressure is generated with an axial piston pump, precisely regulated by the standard proportioning valve.

The good equipment with a proportioning valve in the hydraulics and the finely selectable relief valve allows you to optimize all cutting processes with ECOTRON®. ECOTRON® lets you get the best high pressure cut for your material.

The high-quality reliable pressure intensifier and the large pulsation damper with a storage volume of 1.6 l then ensure then an even pressure signal for a flawless cut.

You get the best equipment with the basic model already.

ECOTRON

40.11/15/19/22/30/37/45

drive power: 11 – 45 kW

operating Pressure: 4.000 bar

output: 1,2 – 4,3 l/min

Advantages at a glance

Equipped as standard with an oil/air cooler, ECOTRON® saves not only money but also spares the environment. The cooler is installed in an oil catch pan which is not just one prerequisite for the CE marking but also environmentally friendly in case of leaks.

Ease of servicing is ensured by a clearly visible pressure gauge in the front pump area as well as a safety valve and high-pressure intensifier at working height. The oil tank is made of aluminium: rust doesn’t stand a chance.

Dual filter units keep foreign matter away from the pressure intensifier and prevent damage.

Stepless pressure adjustment is provided by the proportioning valve installed as standard. The regular features also include processing of the on/off signal of the waterjet valve in the pump. This prevents pressure peaks in the entire high pressure system during the closing of the cutting head. More information is provided in the downloadable presentation.

The large-volume pulsation damper with 1.6 l lessens pressure variations to a minimum of 140 bar and thus ensures good cuts and little wear on high-pressure pipes and components.

THE RELIABLE HEART OF THE PUMP

The ECOTRON® high-pressure intensifier provides maintenance of the suction and pressure valve from the outside without having to remove the valve body.

THE ECOTRON® CONTROL

Meaningful equipment with everything you need:

1) Touch screen for easy operation

2)Control with the machine controller of the waterjet cutting system easily realized

3)Many languages available

4)Operational states visible

5)Operating data memory

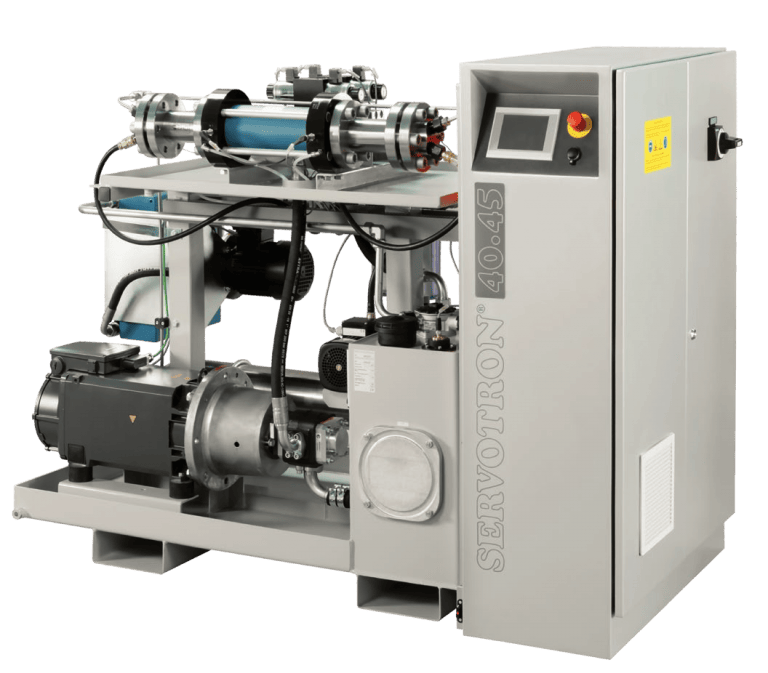

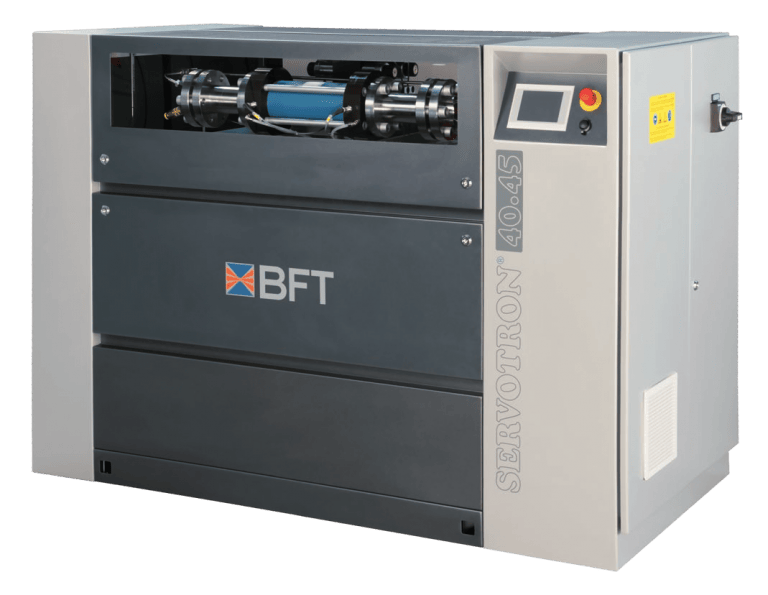

SERVOTRON HIGH PRESSURE PUMP BFT (Austria)

SERVOTRON® is available in the power classes 37 kW and 45 kW. Its operating pressure of 4,000 bar has been considered to be the optimum in the professional waterjet cutting

sector for years.

The Austrian technical control board has confirmed that up to 24% energy can be saved with SERVOTRON® in a comparison with conventional pumps. It is available with a flow

rate of 3.8 l per minute and 4.6 l per minute.

THE ADVANTAGES

1)More than 24 % energy savings

2)Low noise level at < 73 dB (A)

3)Perfect high pressure control

4)Minimal pressure peaks

SERVOTRON®

40.37/40.45+•

drive power: 37 / 45 kW

operating Pressure: 4.000 bar

output: 3,8 / 4,6 l/min

Advantages at a glance

Equipped as standard with an oil/air cooler, SERVOTRON® saves not only money but also spares the environment. The cooler is installed in an oil catch pan which is not just one prerequisite for the CE marking but also environmentally friendly in case of leaks.

Ease of servicing is provided by the convenient pump control. The upcoming valve maintenance is displayed by temperature sensors here. Safety valve and high-pressure intensifier are installed at working height. The durable oil tank is made of aluminium: rust doesn’t stand a chance.

Two filter units keep foreign matter away from the high-pressure intensifier and prevent damage.

The pulsation damper with 2.49 l lessens pressure variations to a minimum of 140 bar and thus ensures good cuts and little wear on pipes and high-pressure components.

THE SERVOTRON® CONTROL

Electronic control with meaningful extras as standard:

1)Different analysis functions through temperature sensors (see Figure)

2) Master-slave function for up to three SERVOTRON® units as standard

3)Profibus connection with machine controller

4)Frequency inverter to control the servo motor

5)Smooth start-up to prevent current peaks

6) Electronic log book for industrial data recording