Types of Manipulators

Manipulator arms are made up of rigid connections that are connected by joints that allow relative movement of adjacent connections.

Mechanical arms have the ability to perform a variety of pre-programmed operations in a variety of industries.

Skilled mechanical arms have been significantly improved and improved in recent years.

It has become easier to work with them as well as maintain them, and there has been an appropriate and optimal connection between

their power, controllability and skill.

Applications of skilled mechanical arms

At the end of the chain there are the components of the mechanical arm of the final operator, which, depending on the application expected

from the robot, can be a clamp or other tools such as accessories. Cutting and welding and the like.

In this sense, there are a variety of skilled mechanical arms that cover a wide variety of industrial and research applications.

These applications include a variety of assembly, cutting and welding activities on production lines to a variety of underwater

operations - such as installation on underwater robots - such as catching and tracking cables or wires, or enclosing complex

objects or specimens such as connecting electrical or hydraulic lines.

Design and construction considerations

What is important in choosing mechanical arms is to choose the simplest possible model that can perform the assigned task at the right time.

The complexity of robot design while increasing performance capabilities can cause problems in controlling, steering, as well

as the reliability and accuracy of the device as well as its maintenance. Choosing and completing a skilled mechanical arm set is a complex matter,

and the robot designer must consider many points. These include the number and types of arms required, the location, the type of controller,

the range of performance space, the maximum and minimum access points, and the type and structure of the control of the arms by the user.

| Type | column | Ceiling |

|---|---|---|

| How to deploy | Fixed | Railroad |

| Control system | Pneumatic | Electronic |

| Motion transmission system | Arm | Tow rope |

| Bearable weight | 5 to 150 kg | |

| Covered space | optional |

Ability to install various gripper

Unload, Load and Switching capability between different modes

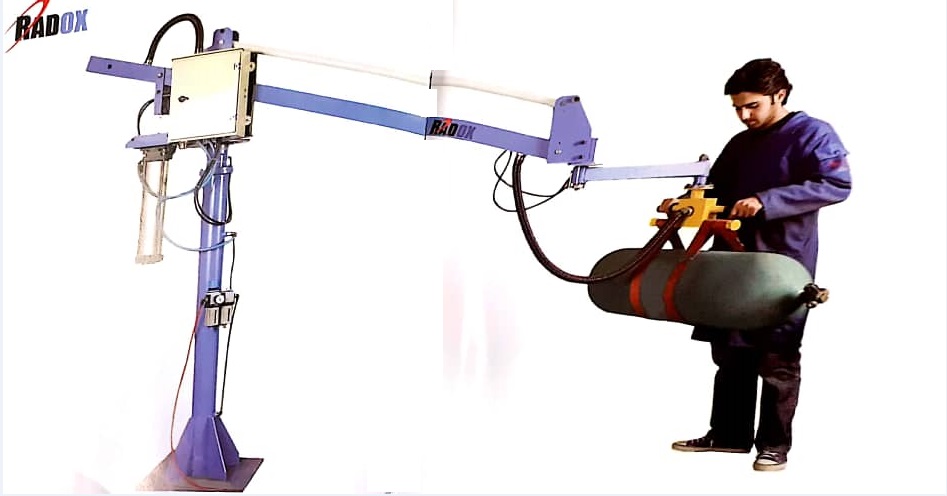

Industrial Manipulators

The use of industrial manipulators in production processes is of great importance in order to facilitate, increase production efficiency, reduce waste and improve the quality of parts and products. Understandably, the manipulators has many uses in the production lines of all manufacturing plants in the world. Due to the simplicity of the mechanism, high speed of operation and ease of operation of the operator, the appropriate manipulator can be used as needed. Repetitive and under load, the system is controlled by a proportional regulator and air jack. Today, due to the urgent need of the industry for manipulator, various types of these devices, depending on the workspace and type of application, are designed and built in fixed and movable forms.