CNC Flame cutting machine

Flame cutting range: Up to 300 mm

Dimensions: All sizes upon customer request

6m * 2m 12m * 3m and other sizes

Cutting material: All metal sheets

(Steel, aluminum, etc)

Options: Marker - X beveler - Pipe cutter 500 mm * 6000 mm

Extra torch- Dust collector tank -Plasma Unit -Height control

Pipe cutter option: Cutting different types of pipes by air gas or plasma

Cutting various shapes on the pipe

Guarantee: 5 years guarantee

After-sale service: 15 yeras

General specification of spider CNC :

Cutting different types of curved surfaces with different wall thicknesses by waterjet, plasma or air gas

Ac Servo motors

Possibility of sending maps by Flash Memory, LAN (network) CAD / CAM software or direct map entry from Auto cad software

Ability to adhere to metal surfaces with different angles by magnet or vacuum method

Ability to move 5 axes of cutting head Possibility of installing plasma torch, air gas and waterjet

FLAME CUTTING CNC MACHINE

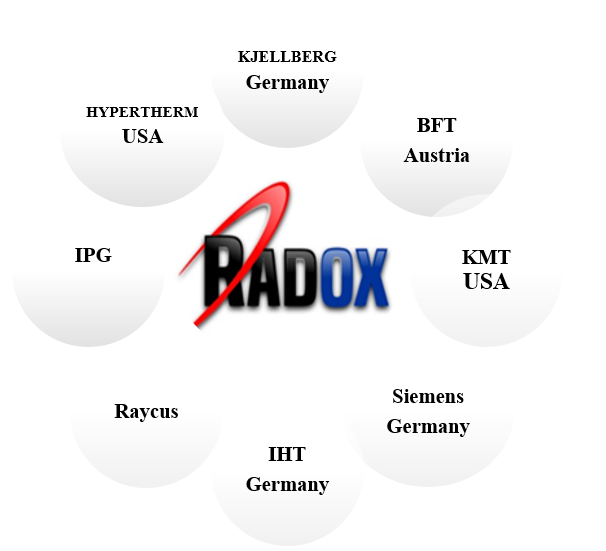

RADOX, by presenting the latest international engineering achievements, in the field of CNC cutting equipment, after years of research and experience, introduced its latest CNC cutting models with FLX and LYNX to the industry. Some of the unique features are described below.

FLX and LYNX CNCs are produced under the supervision of the German company KJELLBERG, and due to the high capabilities and accuracy of these types of CNCs, they have the ability to be installed and compatible with a variety of international plasma units.

The FLX CNC and LYNX CNC controllers are among the latest achievements of RADOX, and one of the advantages of these models is that they are very easy to use for the operator of the device, which can be taught with a simple tutorial.

MODEL LYNX

CNC LYNX GENERAL SPECIFICATION

| Plasma adding capability | Energy Guide ٍ Separate for plasma cable (OPTIONAL) |

| Sheet Align, Nesting, Piercing software | Ac Servo and Double drive engines (two engines on two axles) |

| Z motor, sparkle plug and LM guide and dust collector tank (OPTIONAL) | Integrated chasis with the possibility of adding 5 axis Beveller |

MODEL FLX

CNC FLX GENERAL SPECIFICATION

| Plasma adding capability | Energy Guide ٍ Separate for plasma cable (OPTIONAL) |

|---|---|

| Sheet Align, Nesting, Piercing software | Ac Servo and Double drive engines (two engines on two axles) |

| Z motor, sparkle plug and LM guide and dust collector tank (OPTIONAL) | Interchangeable chasis with the possibility of adding 5 axis Beveller |