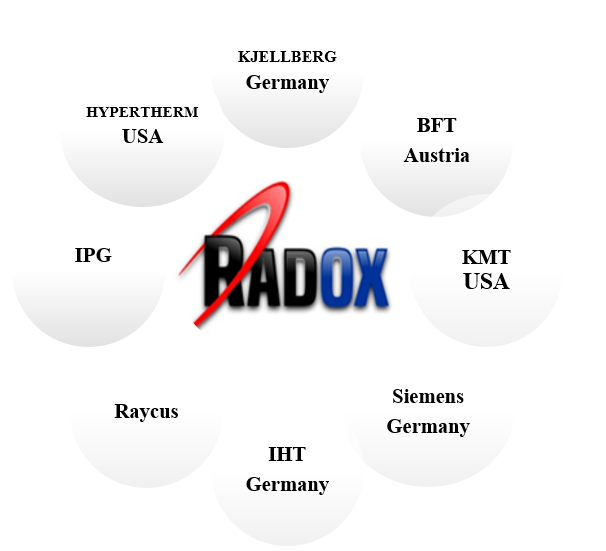

CNC with Hypertherm (USA) PLASMA (large size)

Hypertherm (USA) Plasma models:

Powermax65 SYNC - Powermax85 SYNC - XPR300 plasma - Powermax105 SYNC - MAXPRO200 - Powermax45 XP - Powermax30 XP - XPR170 - Powermax30 AIR - Powermax125 - HyPerformance HPR400XD - HyPerformance HPR800XD

Plasma Cutting range: 0.5 mm - 38 mm

Flame cutting range: Up to 300 mm

Accuracy: ± 0.25 mm

Dimensions: All large sizes upon customer request

12m * 3m , 26m * 6m *delivering other larger sizes is negotiable*

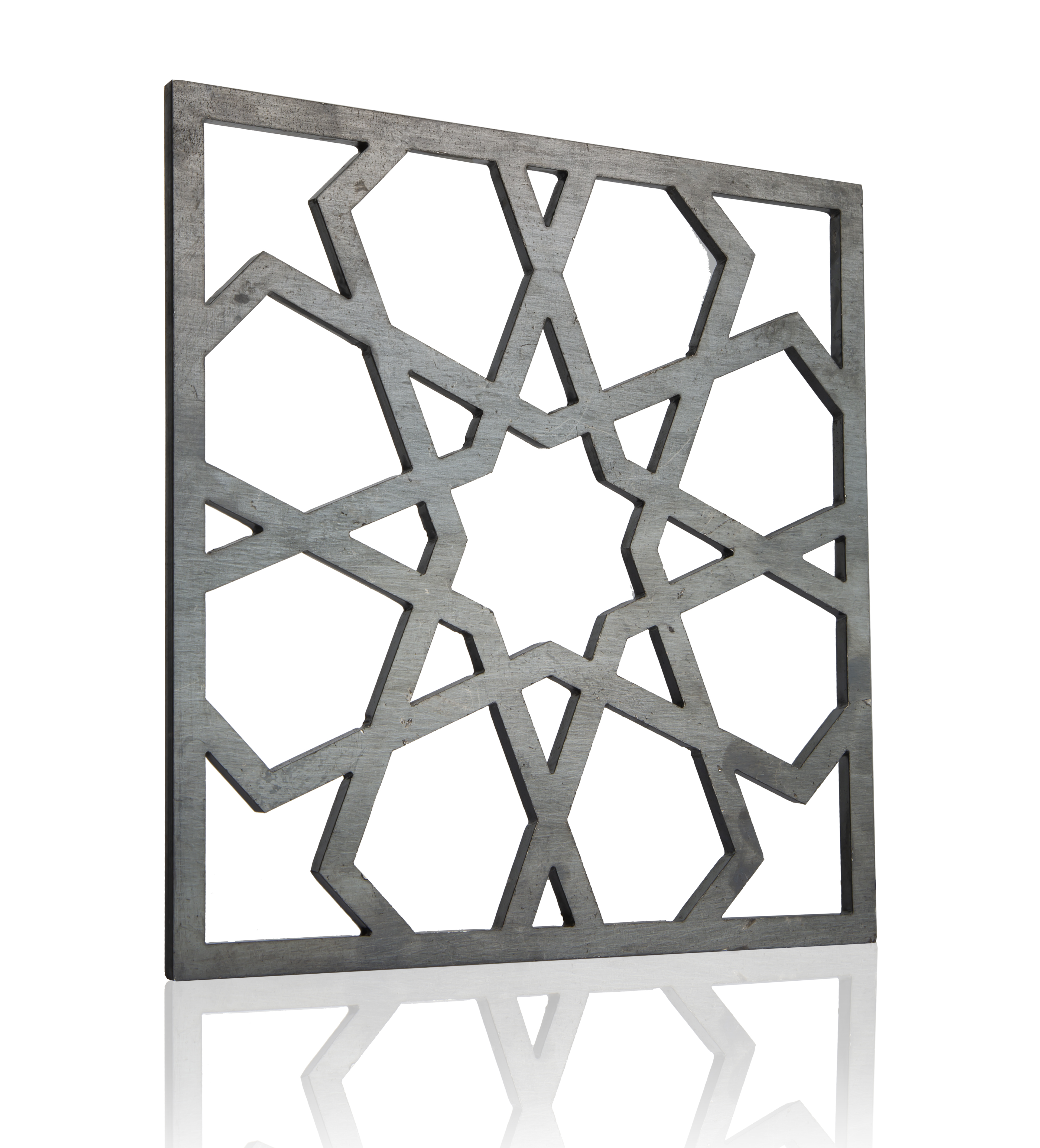

Pictures | Large sizes |

|---|---|

| 12 m * 3 m |

| 26 m * 6 m |

Cutting material: All metal sheets

(Steel, aluminum, etc)

Guarantee: 5 years CNC guarantee and 1 year Plasma guarantee

After-sale service: 15 yeras

Applications:

RADOX cutting machines can be used in wide variety of manufacturing industries such as:

1) Automotive industry

2) Aerospace & energy

3) Shipbuilding industry

4) Oil and Gas industry

5) Agricultural machinery

6) Machinery manufacturers

7) Home appliances and equipment

8) Elevators & escalators

9) Electrical panels

10) Lighting equipment

11) Heating and refrigeration industries

12) Hospital & Lab equipment

RADOX Plasma CNC cutting machines advantages:

1) Low energy consumption

2) Maintenance free operation

3) High speed

4) High quality

Brand, type & Description | Item | Row |

|---|---|---|

| LYNX (Integrated chassis) | CNC model | 1 |

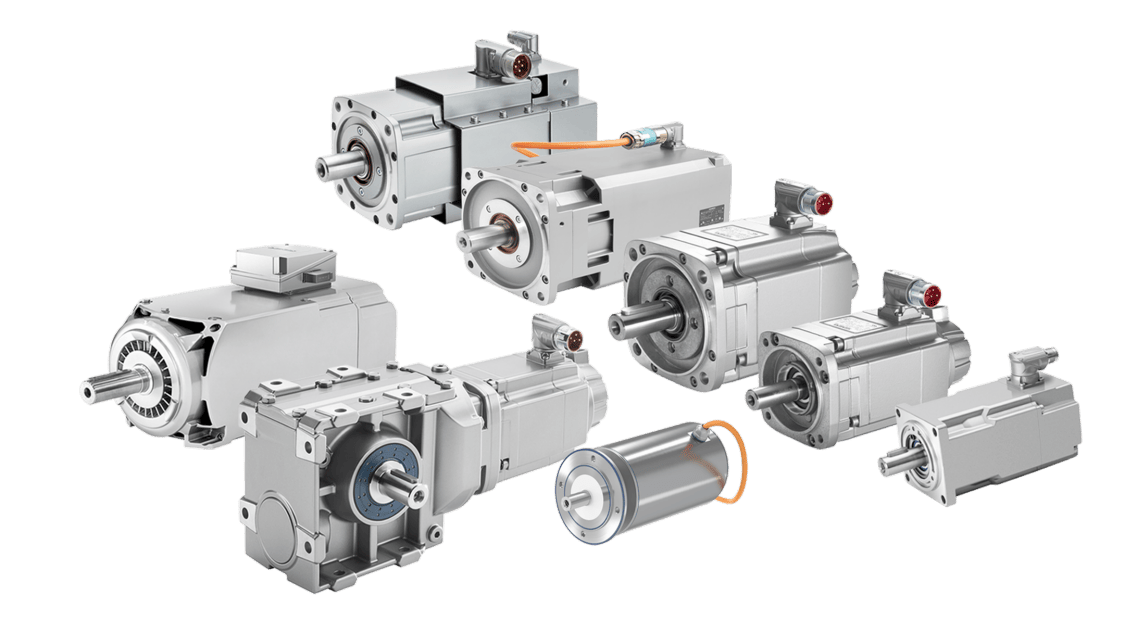

| Siemens (GERMANY) | Ac Servomotor | 2 |

| PHC Hypertherm (USA) | Height control | 3 |

| HIWIN (TAIWAN) | LM guide | 4 |

| Koike (JAPAN( | Nozzle | 5 |

| MAX 105 Hypertherm (USA) | Plasma unit | 6 |

| ✓ | Dust collector tank | 7 |

| ✓ | possibility of adding 5 axis CNC Beveler | 8 |

| ✓ | Flame Torch | 9 |

| 0.5- 38 mm | Plasma cutting thickness | 10 |

| Up to 300 mm | Flame cutting thickness | 11 |

| (for Plasma cable) | Energy guide | 12 |

| 3 | Number of gearboxes | 13 |

| Hiwin | Sparkle | 14 |

| 19 inches | Monitor | 15 |

| 4980 kg | Machine weight | 16 |

Siemens Servomotors (GERMANY)

Siemens Servomotors are recognized for precision, robustness, and wide range of designs, Siemens SIMOTICS S synchronous motors are the first choice for highly dynamic and exact motion paths. Users benefit from a wide selection of products featuring high dynamic performance, precision, compactness, efficiency and ruggedness.

Choose the perfect synchronous servo motor with features to improve any application

1) Wide torque range

2) Industry-leading efficiency ratings

3) Range of cooling types and protection classes

4) Various built-in transmitters

5) Integrated parking brake

Hiwin LM guide (TAIWAN)

A linear guideway allows a type of linear motion that utilizes rolling elements such as balls or rollers. By using re-circulating rolling elements between the rail and the block, a linear guideway can achieve high precision linear motion.

Advantages and Features of HIWIN Linear Guideways:

1) High positional accuracy

2) Long life with high motion accuracy

3) High speed motion is possible with a low driving force

4) Equal loading capacity in all directions

5) Easy installation

6) Easy lubrication

7) Interchangeability

Hiwin linear guideways provide a type of linear motion that utilizes re-circulating rolling elements between a profiled rail and a bearing block. The coefficient of friction on a linear guideway is only 1/50 compared to a traditional slide and are able to take loads in all directions. With these features, a linear guideway can achieve high precision and greatly enhanced moving accuracy. Hiwin Corporation offers multiple linear guideway series and each series features different options for sizes, loading capabilities, accuracies, and more.

Koike Nozzle (JAPAN)

Only the original Koike oxy fuel cutting tips: 102, 102HC, 102-D7, 103, 103-D7, 106, 106HC, 106-D7, 107 and 107-D7 are designed and manufactured to provide high quality cutting, safe operation, longer cutting life, high speed cutting and save gas costs. In addition our 100 series cutting tip can be used to replace Airco® style cutting tips. Click here to view Cutting Tip Chart»

All Koike 100 Series cutting tips are designed to mix the fuel and the oxygen used for preheating inside the cutting tip. This is recognized as one of the safest methods. Koike 100 series torches carry a lifetime warranty against a damaging sustained flashback while using genuine Koike cutting tips (excludes IK-82).

The Koike D7 cutting tips are one of the most technically advanced cutting tips available, providing safety and accuracy while saving money in time and gas costs. Our high speed D7 Series of Cutting tips with a divergent tip increase cutting speed 20-28% over standard tips and Gas consumption is reduced up to 26%. A stainless steel liner helps them last up to 5 times longer than other tips.

Hypertherm PHC height control (USA)

Hypertherm’s Sensor™ plasma torch height control (PHC) is an easy-to-use, highly reliable voltage-sensing height control for conventional plasma piercing and cutting applications. Requiring no operator input while cutting, the controller offers separate settings for both pierce and cut heights to automatically position the torch.

The Sensor PHC is compatible with any computer numeric control (CNC) and a broad range of plasma systems, and is easy to install on new or existing conventional plasma cutting tables. The Sensor PHC delivers improved performance at a significantly lower cost than other height control solutions.

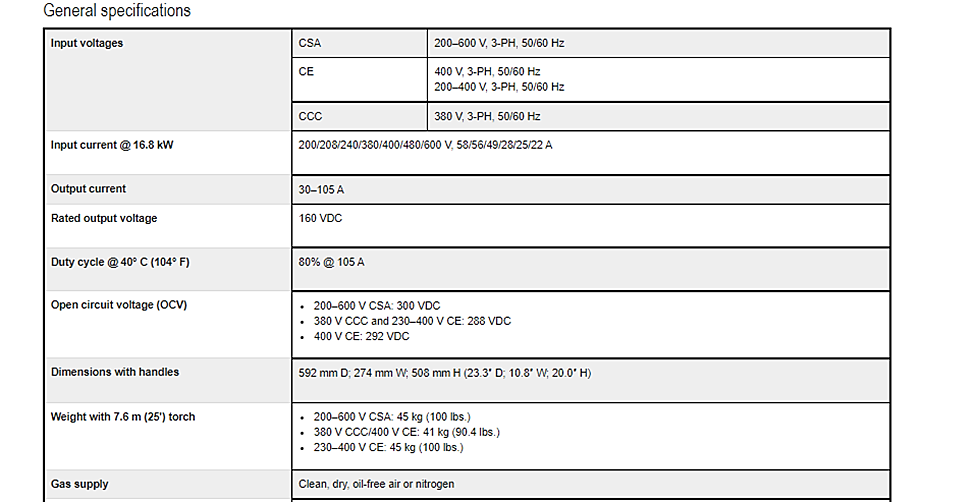

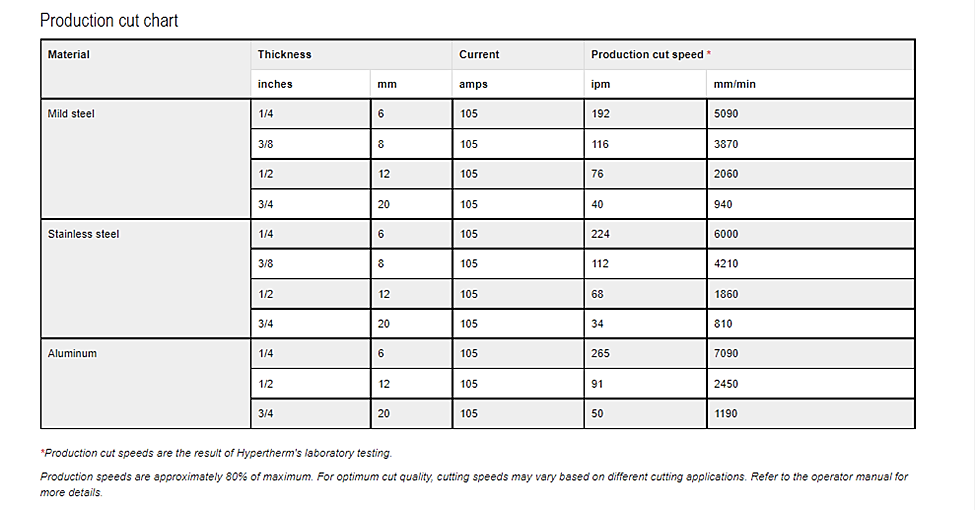

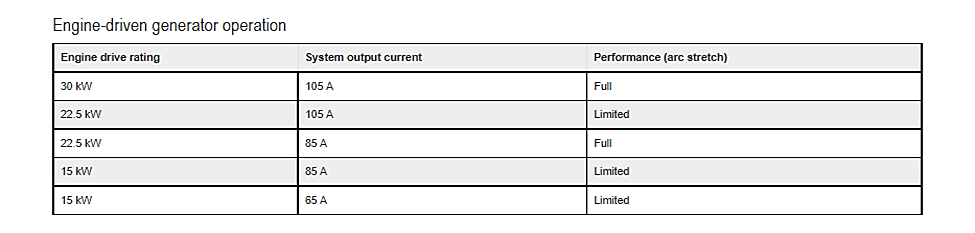

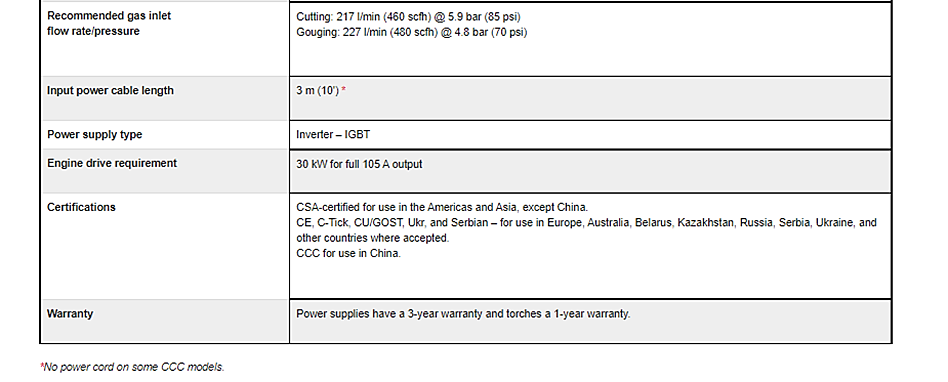

Hypertherm plasma unit MAX 105 (USA) specification