CNC with Kjellberg (Germany) Plasma (large size)

Kjellberg (Germany) Plasma models:

1. Smart Focus: Smart Focus 400 - Smart Focus 300 - Smart Focus 200 - Smart Focus 170 - Smart Focus 130

2. HiFocus: HiFocus 600i - HiFocus 440i - HiFocus 360i - HiFocus 280i - HiFocus 161i - HiFocus 130 - HiFocus 80i

3. CutFire: CutFire 100i

Plasma Cutting range: 0.5 mm - 80 mm

Flame cutting range: Up to 300 mm

Accuracy: ± 0.25 mm

Dimensions: All large sizes upon customer request

12m * 3m , 26m * 6m *delivering other larger sizes is negotiable*

Pictures | Large size |

|---|---|

| 12 m * 3 m |

| 26 m * 6 m |

Cutting material: All metal sheets

(Steel, aluminum, etc)

Guarantee: 5 years CNC guarantee and 1 year Plasma guarantee

After-sale service: 15 yeras

Applications

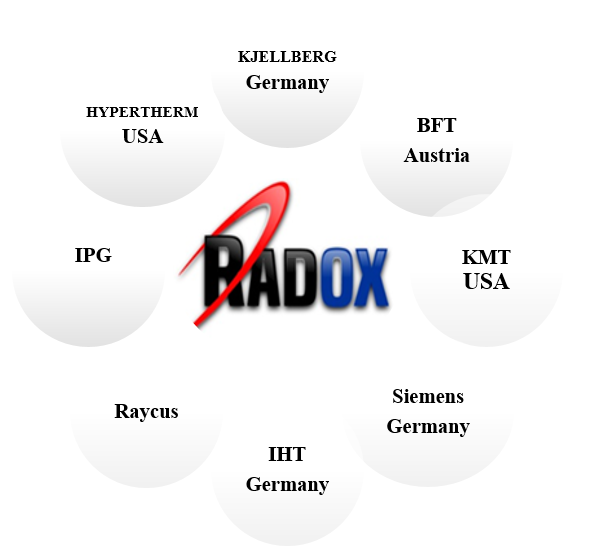

RADOX cutting machines can be used in wide variety of manufacturing industries such as:

1) Automotive industry

2) Aerospace & energy

3) Shipbuilding industry

4) Oil and Gas industry

5) Agricultural machinery

6) Machinery manufacturers

7) Home appliances and equipment

8) Elevators & escalators

9) Electrical panels

10) Lighting equipment

11) Heating and refrigeration industries

12) Hospital & Lab equipment

RADOX Plasma CNC cutting machines advantages:

1) Low energy consumption

2) Maintenance free operation

3) High speed

4) High quality

Brand, type & Description | Item | Row |

|---|---|---|

| LYNX (Integrated chassis) | CNC model | 1 |

| Siemens (GERMANY) | Ac Servomotor | 2 |

| IHT M 4000 (GERMANY) | Height control | 3 |

| HIWIN (TAIWAN) | LM guide | 4 |

| Koike (JAPAN( | Nozzle | 5 |

| KJELLBERG Smart Focus 300 (GERMANY) | Plasma unit | 6 |

| Possibility to add | Plasma marker | 7 |

| ✓ | Dust collector tank | 8 |

| ✓ | Under water Plasma | 9 |

| ✓ | possibility of adding 5 axis CNC Beveler | 10 |

| ✓ | Flame Torch | 11 |

| 0.5- 80 mm | Plasma cutting thickness | 12 |

| Up to 300 mm | Flame cutting thickness | 13 |

| (for Plasma cable) | Energy guide | 14 |

| 3 | Number of gearboxes | 15 |

| ✓ | Sparkle | 16 |

| 19 inches | Monitor | 17 |

| 5740 kg | Machine weight | 18 |

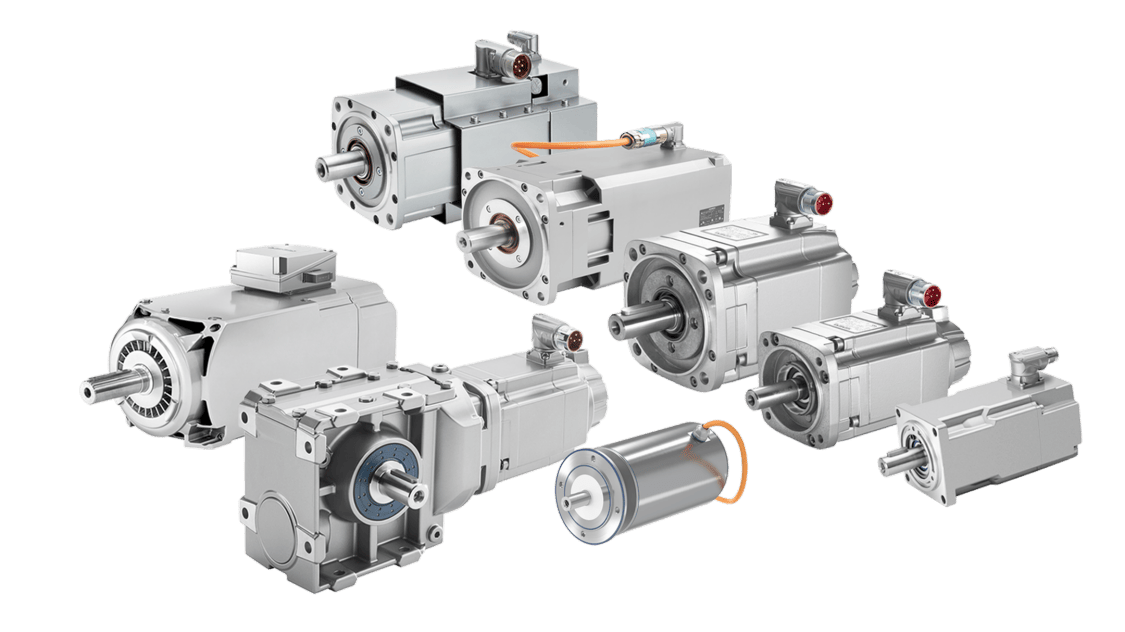

Siemens Servomotors (GERMANY)

Siemens Servomotors are recognized for precision, robustness, and wide range of designs, Siemens SIMOTICS S synchronous motors are the first choice for highly dynamic and exact motion paths. Users benefit from a wide selection of products featuring high dynamic performance, precision, compactness, efficiency and ruggedness.

Choose the perfect synchronous servo motor with features to improve any application

1) Wide torque range

2) Industry-leading efficiency ratings

3) Range of cooling types and protection classes

4) Various built-in transmitters

5) Integrated parking brake

Hiwin LM guide (TAIWAN)

A linear guideway allows a type of linear motion that utilizes rolling elements such as balls or rollers. By using re-circulating rolling elements between the rail and the block, a linear guideway can achieve high precision linear motion.

Advantages and Features of HIWIN Linear Guideways:

1) High positional accuracy

2) Long life with high motion accuracy

3) High speed motion is possible with a low driving force

4) Equal loading capacity in all directions

5) Easy installation

6) Easy lubrication

7) Interchangeability

Hiwin linear guideways provide a type of linear motion that utilizes re-circulating rolling elements between a profiled rail and a bearing block. The coefficient of friction on a linear guideway is only 1/50 compared to a traditional slide and are able to take loads in all directions. With these features, a linear guideway can achieve high precision and greatly enhanced moving accuracy. Hiwin Corporation offers multiple linear guideway series and each series features different options for sizes, loading capabilities, accuracies, and more.

Koike Nozzle (JAPAN)

Only the original Koike oxy fuel cutting tips: 102, 102HC, 102-D7, 103, 103-D7, 106, 106HC, 106-D7, 107 and 107-D7 are designed and manufactured to provide high quality cutting, safe operation, longer cutting life, high speed cutting and save gas costs. In addition our 100 series cutting tip can be used to replace Airco® style cutting tips. Click here to view Cutting Tip Chart»

All Koike 100 Series cutting tips are designed to mix the fuel and the oxygen used for preheating inside the cutting tip. This is recognized as one of the safest methods. Koike 100 series torches carry a lifetime warranty against a damaging sustained flashback while using genuine Koike cutting tips (excludes IK-82).

The Koike D7 cutting tips are one of the most technically advanced cutting tips available, providing safety and accuracy while saving money in time and gas costs. Our high speed D7 Series of Cutting tips with a divergent tip increase cutting speed 20-28% over standard tips and Gas consumption is reduced up to 26%. A stainless steel liner helps them last up to 5 times longer than other tips.

Height control IHT M 4000 (GERMANY)

The M4000 BAS height control unit is an easy-to-use unit to adjust the torch height on all Smart Focus, HiFocus, FineFocus, CutFire and PA-S power sources. The robust and precise mechanics guarantees an excellent and continuous cutting quality as well as an exact adjustment of the distance between torch and workpiece. The required torch height is adjusted in mm/inch. It is controlled via the cutting current which is electronically measured and read during the cutting process. Thereby, the cathode wear can be observed continuously.

M 4000 BAS (GERMANY)

Automatic clearance control for standard plasma cutting machines

One of the most important components when cutting with plasma is the precise clearance control.

The M 4000 BAS system provides all required characteristics for a precise cut. The system adapts to all common cutting machines, regardless if new installations or retrofit.

Process: Plasma

M 4000 BAS consists of the LINEAR DRIVE BODY BAS, the GUIDING RAIL with 220 or 350 mm stroke and the OPERATOR INTERFACE with a built-in arc control system, motor controller and operator panel.

The operation of the M 4000 BAS system is done by BAS OPERATOR INTERFACE and digital signals and can be operated manually or centrally via a CNC. The setting of pierce height and cutting height is in millimeter, the setting of pierce delay in seconds. The control of cutting height is done using the ARC voltage.

The torch is protected using excellent 3D collision protection in the torch clamp and a vertical collision detection.

Options: Collision detection and Contact Sensor

KJELLBERG plasma unit Smart Focus 300 (GERMANY)

With just a few settings the new plasma cutting units of the Smart Focus series achieve excellent results in the cutting range from 1 to 80 mm. Even under challenging conditions highest cutting quality and speed are realised. In such cases, we use our well-proven cutting technologies, e.g. Contour Cut for cutting mild steel. The optimised gas control units and torches protect the consumables, reduce the gas consumption and the costs per cutting metre. As a further development of the Contour Cut technology the new Silent Cut technology reduces the sound pressure level by up to 15 dB(A) during cutting with currents between 60 and 160 A.

Technical data

Power source Smart Focus 300

Mains voltage* 3x 400 V, 50 Hz

Cutting current 35 - 300 A

Marking current 10 - 50 A

Cutting range

Maximum 80 mm

Recommended 1 - 60 mm

Piercing 40 mm

Plasma gases O2, Ar / H2, N2, air

Piercing Ar, N2

Dimensions (L x W x H) 1030 x 680 x 1450 mm

Weight 820 kg

Plasma machine torch PerCut 2000

Quick change head PerCut 4000

Torches & gas control – intelligent redevelopment

Either manual or automated gas supply units are available for the Smart Focus series. With these the user achieves best cutting results with highest, reproducible quality. The manual gas supply unit PGE-300 now allows for plasma cutting with air as plasma gas.

The new torches PerCut 2000 and PerCut 4000 have been improved compared to the preceding models. They provide precise cuts and highest cutting speeds. Their unique cooling system up to the torch tip guarantees longest consumable life and reduces the gas consumption and costs per cutting metre.