Spider cutting CNC machine with Kjellberg (Germany) plasma

Kjellberg (Germany) Plasma models:

Smart Focus 400 - Smart Focus 300 - Smart Focus 200 - Smart Focus 170 - Smart Focus 130

HiFocus 600i neo - HiFocus 440i neo - HiFocus 360i neo - HiFocus 280i neo - HiFocus 161i neo - HiFocus 130 neo - HiFocus 80i

CutFire 100i

Plasma Cutting range: 0.5 mm - 80 mm

Flame cutting range: Up to 300 mm

Accuracy: ± 0.25 mm

Dimensions: All sizes upon customer request

1.5 m * 1.5 m and other sizes

Cutting material: All metal sheets

(Steel, aluminum, etc)

Guarantee: 5 years CNC guarantee and 1 year Plasma guarantee

After-sale service: 15 yeras

Applications

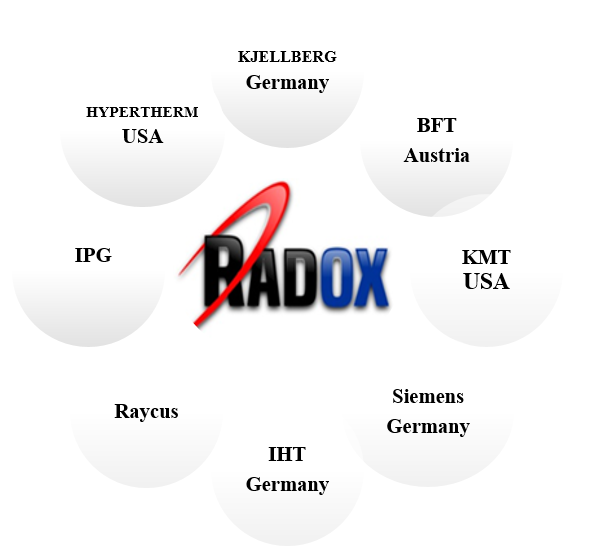

RADOX cutting machines can be used in wide variety of manufacturing industries such as:

1) Automotive industry

2) Aerospace & energy

3) Shipbuilding industry

4) Oil and Gas industry

5) Agricultural machinery

6) Machinery manufacturers

7) Home appliances and equipment

8) Elevators & escalators

9) Electrical panels

10) Lighting equipment

11) Heating and refrigeration industries

12) Hospital & Lab equipment

RADOX Plasma CNC cutting machines advantages:

1) Low energy consumption

2) Maintenance free operation

3) High speed

4) High quality

General specification of spider CNC :

Cutting different types of curved surfaces with different wall thicknesses by waterjet, plasma or air gas

Ac Servo motors

Possibility of sending maps by Flash Memory, LAN (network)

CAD / CAM software or direct map entry from Auto cad software

Ability to adhere to metal surfaces with different angles by magnet or vacuum method

Ability to move 5 axes of cutting head

Possibility of installing plasma torch, air gas and waterjet

KJELLBERG plasma unit Smart Focus 300 (GERMANY)

With just a few settings the new plasma cutting units of the Smart Focus series achieve excellent results in the cutting range from 1 to 80 mm. Even under challenging conditions highest cutting quality and speed are realised. In such cases, we use our well-proven cutting technologies, e.g. Contour Cut for cutting mild steel. The optimised gas control units and torches protect the consumables, reduce the gas consumption and the costs per cutting metre. As a further development of the Contour Cut technology the new Silent Cut technology reduces the sound pressure level by up to 15 dB(A) during cutting with currents between 60 and 160 A.

Technical data

Power source Smart Focus 300

Mains voltage* 3x 400 V, 50 Hz

Cutting current 35 - 300 A

Marking current 10 - 50 A

Cutting range

Maximum 80 mm

Recommended 1 - 60 mm

Piercing 40 mm

Plasma gases O2, Ar / H2, N2, air

Piercing Ar, N2

Dimensions (L x W x H) 1030 x 680 x 1450 mm

Weight 820 kg

Plasma machine torch PerCut 2000

Quick change head PerCut 4000

Torches & gas control – intelligent redevelopment

Either manual or automated gas supply units are available for the Smart Focus series. With these the user achieves best cutting results with highest, reproducible quality. The manual gas supply unit PGE-300 now allows for plasma cutting with air as plasma gas.

The new torches PerCut 2000 and PerCut 4000 have been improved compared to the preceding models. They provide precise cuts and highest cutting speeds. Their unique cooling system up to the torch tip guarantees longest consumable life and reduces the gas consumption and costs per cutting metre.