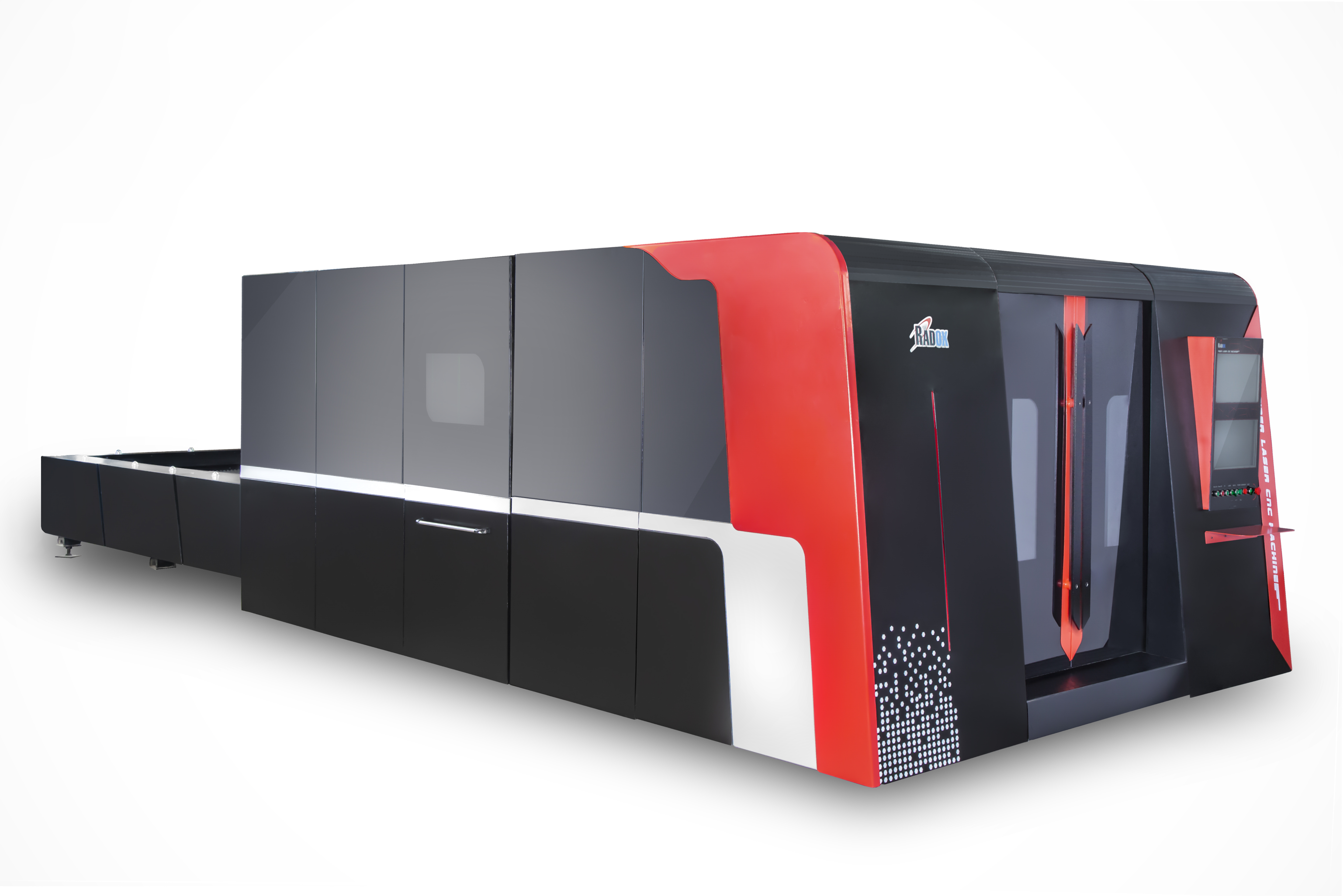

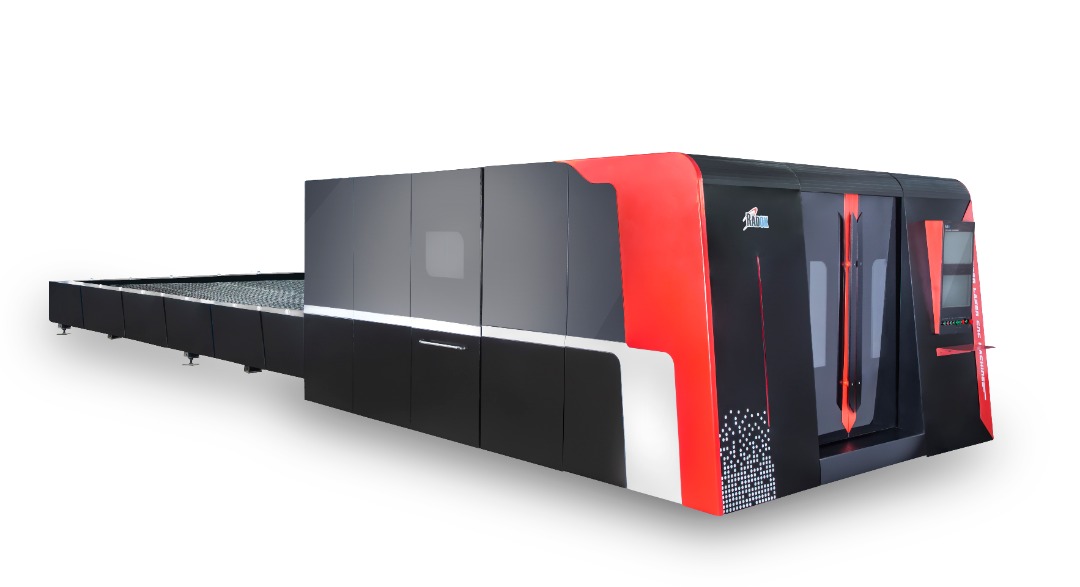

Fiber Laser cutting CNC machine Large size (Enclosed type)

Laser power: 1 kw - 100 kw

1 kw 1.5 kw 2 kw 3 kw 4 kw 6 kw 8 kw 15 kw and high powers up to 100 kw

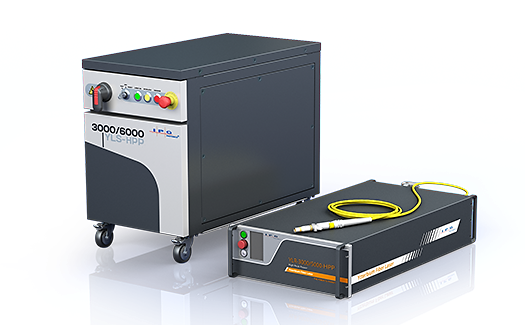

Laser source: IPG

Cutting speed and thickness: 1 kw 1.5 kw 2 kw 3 kw 4 kw 6 kw 8 kw 15 kw

Download Cutting speed and thickness: 1 kw

Download Cutting speed and thickness: 1.5 kw

Download Cutting speed and thickness: 2 kw

Download Cutting speed and thickness: 3 kw

Download Cutting speed and thickness: 4 kw

Download Cutting speed and thickness: 6 kw

Download Cutting speed and thickness: 8 kw

Download Cutting speed and thickness: 12 kw

Download Cutting speed and thickness: 15 kw

Dimensions: All large sizes upon customer request

12m * 2m , 12m * 12m *delivering other larger sizes is negotiable*

pictures | Sizes |

| 12 m * 2 m |

| Super large size12 m * 12 m |

Cutting material: All metal sheets

Mild steed - Stainless steel - Aluminium - Brass - Copper and other metal sheets

Guarantee: 2 years guarantee

After-sale service: 15 yeras

Applications:

1) RADOX cutting machines can be used in wide variety of manufacturing industries such as:

2) Automotive industry

3) Aerospace & energy

4) Shipbuilding industry

5) Oil and Gas industry

6) Agricultural machinery

7) Machinery manufacturers

8) Home appliances and equipment

9) Elevators & escalators

10) Electrical panels

11) Lighting equipment

12) Heating and refrigeration industries

13) Hospital & Lab equipment

Brand, type & Description | Item | Row |

| IPG 1000 – 100000 W | Laser power | 1 |

| 1550*3050*150 mm | Working dimensions | 2 |

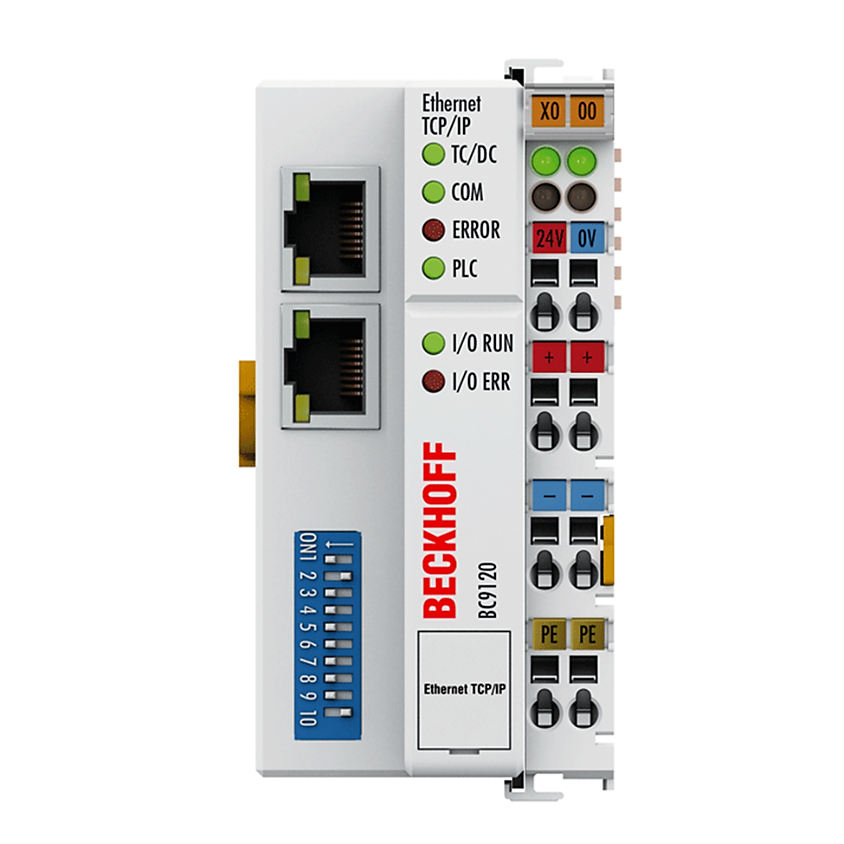

| Beckhoff Germany | Servo motor | 3 |

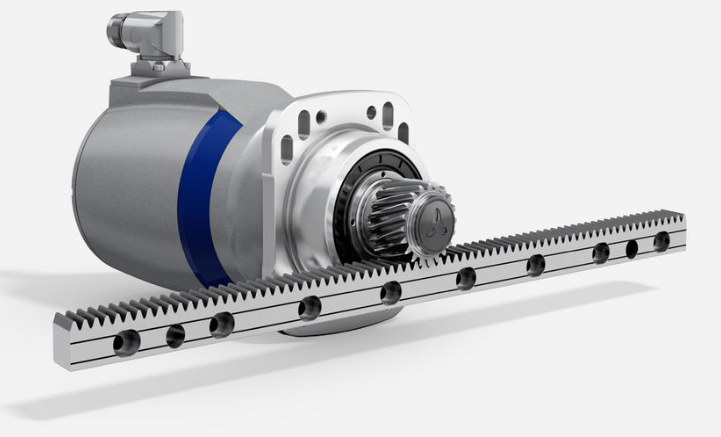

| Wittenstein Germany | Rack & Pinion | 4 |

| Shimpo Japanese brand | Gearbox | 5 |

| Precitec Light Cutter Auto Focus USA | Cutting head | 6 |

| Japanese brand SMC (Able to control automatically through the controller) | Oxygen control valve | 7 |

| Hiwin Taiwan brand | Linear | 8 |

| Omron Japanese brand | Electronic equipment | 9 |

| TFLW | Chiller | 10 |

| Beckhoff CNC Germany | CNC control system | 11 |

| Fully automatic | Oiling system | 12 |

| Suction from under the table Backward | Suction system | 13 |

| From reputable brands | Pneumatic | 14 |

| SIEMENS | Contactor, Fuse and switches | 15 |

| Korea Autonics | Sensor | 16 |

| Mild steel/al | X Axis | 17 |

| Equipped with suction system, camera & monitor Metal with protective glass | Cabin | 18 |

| 2 cams for cabin | Camera | 19 |

| 150 mm | Focusing lenses | 20 |

| 3050 mm | X Axis (Rack & Pinion) | 21 |

| 1550 | Y Axis (Rack & Penion) | 22 |

| 150 | Z Axis (Rack & Penion) | 23 |

| 80 m/min | Rapid traverse (X & Y Axis) | 24 |

| 1 G | Acceleration | 25 |

| Programmable up to max 50 m/min | Feed rate | 26 |

| Motorized exchange table | Table | 27 |

| 4200 kg (open type CNC laser cutting machine 1kw- 3 kw) 6200 kg (CNC laser cutting machine equipped with cabin & table changer for more than 3 kw) | Machine weight | 28 |

RADOX Fiber laser CNC cutting machines advantages:

1) Low energy consumption

2) Maintenance free operation

3) High quality

4) High speed

IPG Source

Laser source is the core spare part of fiber laser marker. Popular brands in market are IPG and Raycus. Most of us are familiar with IPG, best-selling laser source among overseas market. IPG is the leading developer and manufacturer of high-performance fiber lasers sources in numerous markets.

Benefits of IPG Fiber Lasers

IPG fiber lasers are the most compact and energy efficient lasers on the market, added benefits include:

Virtually maintenance free

Reliably operates even in the harshest industrial environments including extreme vibration, dirt, humidity and temperature changes

Flexible beam delivery supports easy production integration

Delivers the widest breadth of output powers, wavelengths and modes of operation

High flexibility in choosing operating parameters.

5-10 times more efficient in energy conversion than legacy CO2 lasers

Wall plug efficiencies of 45% to over 50% exceed any alternative laser technologies

PRECITEC Smart LASER CUTTING HEADS (USA)

ProCutter 2.0 - Laser cutting with power up to 30 kW

Efficient - automated - persistent

1000-times reliability in use: the ProCutter 2.0 impresses worldwide with its high performance and automation. Its reliability and load capacity in flatbed and tube cutting systems has been perfected - up to a maximum laser power of 30 kW.

Advantages

Maximum productivity thanks to superior technologyWith the ProCutter 2.0, cutting processes that were previously hidden away can now be used in an industrially stable manner. It is not necessary anymore to choose between high quality and high speed. Now both are possible - increased machine utilization and a shorter payback period. The amount of rework is reduced to a minimum.With the new ProCutter 2.0 generation, the highest cutting speeds can be achieved that were previously unthinkable. The cutting head works trouble-free up to 30 kW laser power thanks to its sophisticated cooling concept and the extended travel paths. If the full laser power is not required, the cutting speed can still be increased by up to 25% compared to the predecessor product due to the optimized design.

Intelligent sensors at its best

Component quality and process stability remain permanently constant: fluctuations in the process or in the quality of the material to be cut are compensated without the need for intervention by the machine operator. With PierceTec - automated piercing of the material - you achieve consistent hole and surface quality and can reduce the amount of rework required. PierceTec saves cycle time and operating costs.Smart sensors integrated into the cutting head permanently monitor the condition of critical components or cutting process parameters. The sensors also provide the basis for planned maintenance and efficient utilization of spare parts. This ensures even safer operation and reduces follow-up costs.It is also possible to access the data via mobile devices and to visualize the current status in the ProCutter APP or to query error messages.

WITTENSTEIN Racks and Pinions (Germany)

WITTENSTEIN alpha also offers system components such as pinions and racks for your ideal drive system.

With their precise tooth geometry, all pinion variants are optimally tailored to the various output types, for example flange, shaft or system output. In combination with innovative INIRA racks or one of the standard versions, WITTENSTEIN provideS you with exact-fit system components for your drive solution.

RACK

PENION

Pinions adapted to gearbox and rack

Wide range available

Factory-assembled pinions available

Beckhoff servomotors (Germany)

Rotary servomotors for positioning tasks with the highest demands on dynamics and performance

The highly efficient rotary servomotors offer the perfect solution for every application. The motors are available either in the version with innovative One Cable Technology (OCT) or with a classic 2-cable standard.

Highly dynamic and flexible

The AM8000 synchronous servomotors are characterized by high dynamics, energy efficiency, and reduced life cycle costs. Seven sizes and up to four stack lengths cover all power ranges. On request, the AM8000 motors are also offered with a third-party cooling system to increase power. The servomotors are available with different windings, which are optimally matched to the Beckhoff servo drives from the AX5000 and AX8000 series. Due to the sophisticated Beckhoff modular system, mechanical adjustments can be implemented quickly. Different ordering options for encoders, holding brakes, and connection options leave no customer wishes unfulfilled. Cross profiles and rotatable Speedtec connectors allow quick installation.

With the AM8500 series, the servomotor range is extended by a complete series with an increased rotor moment of inertia. Integrated OCT safety encoders and a resolution of 24 bits allow the realization of applications with the highest requirements for precision and synchronism. Depending on the requirements, the motors can be equipped with additional options for higher protection classes. With the data programmed as standard in the encoders, the natural cogging can be enormously reduced, which enables perfect concentricity at low speeds.

SHIMPO High Precision Gearboxes (JAPAN)

At SHIMPO, servo grade gearboxes were designed to provide the ultimate flexibility and ease of configuration for machine builders across the globe.

SHIMPO hold the concept of modularity of design in the highest regard, and we have instilled that fundamental belief within the design of each of these series. When paired with SHIMPO expertise of high volume production and quality control practices, SHIMPO provides our OEM customers’ unmatched performance, consistency, and overall value.

SHIMPO series utilize different types of gearing technologies – planetary, worm, rotary stage – yet each achieves the highest level of precision and performance within its competitive class.

Beckhoff CNC CONTROL SYSTEM (Germany)

Twincat CNC By Beckhoff

TwinCAT CNC offers complete CNC functionality as a pure PC-based software solution.

TwinCAT CNC covers the complete range of classic CNC path control, including high-end systems for complex motion and kinematics requirements. The powerful, continuously evolving PC platform and the hard real-time base of the TwinCAT realtime kernel provide the foundation for the CNC Software.

Siemens contactor, Fuse & Switches (GERMANY)

The industry's most trusted safety switches

Siemens safety switches provide superior performance and application flexibility. An extended array of accessories and replacement parts reduce installation and operating costs. Siemens switches feature quick make and break operation and visible blade construction. Available in 30-1200 amps, fusible and non-fusible, AC and DC applications, and a variety of NEMA rated enclosures.

Whether switching normal motors or high-efficiency motors (IE3), whether reversing or star-delta starting from the smallest to the largest power range, whether classic screwing or connecting using spring-cage technology or direct digital control. Siemens motor contactors can do all this and much more. No drive is too small or no motor start-up too heavy.

Switching of electric drives or motors: a classic product with a decades-old functional principle interpreted in a modern and future-oriented way: these are Siemens contactors, a generalist for switching motors.

Omron electronic equipment (JAPAN)

Founded in 1933, OMRON is a high-tech multinational enterprise group. Its business fields include 5 major fields, branches in 80 countries around the world, 300 bases, and about 35,000 employees.

Through global bases, we provide customers with the latest technology, best quality products, and global services in each business field.

TONGFEI TFLW WATER CHILLER FOR FIBER LASER

Application

•Fiber lasers for cladding, welding and cutting

•Fiber lasers for marking and 3D printing

Functions and Features

•Circulating pump made from stainless steel features large flow, high head, low noise and long service life. Besides, such components as water tank, pipeline and cooling valves are also made from stainless steel.

•LCD controller is utilized for real-time display of cooling water temperature. Full-automatic CPU can realize man-machine interaction, making it visual and easy-to-operate. Water temperature control accuracy can achieve±1̊C. In addition, the controller featuring automatic fault diagnosis can display fault points on the screen, hence reminding the user of rapid processing.

•RS485 communication interface can be added to implement communication function.

•It serves multiple functions with passive alarm and remote control terminals, making it easy to realize integral control and monitoring of CNC system.

•Dual-temp water chillers can cool the main circuit and external optic circuit simultaneously, which are the optimal choice for lasers.