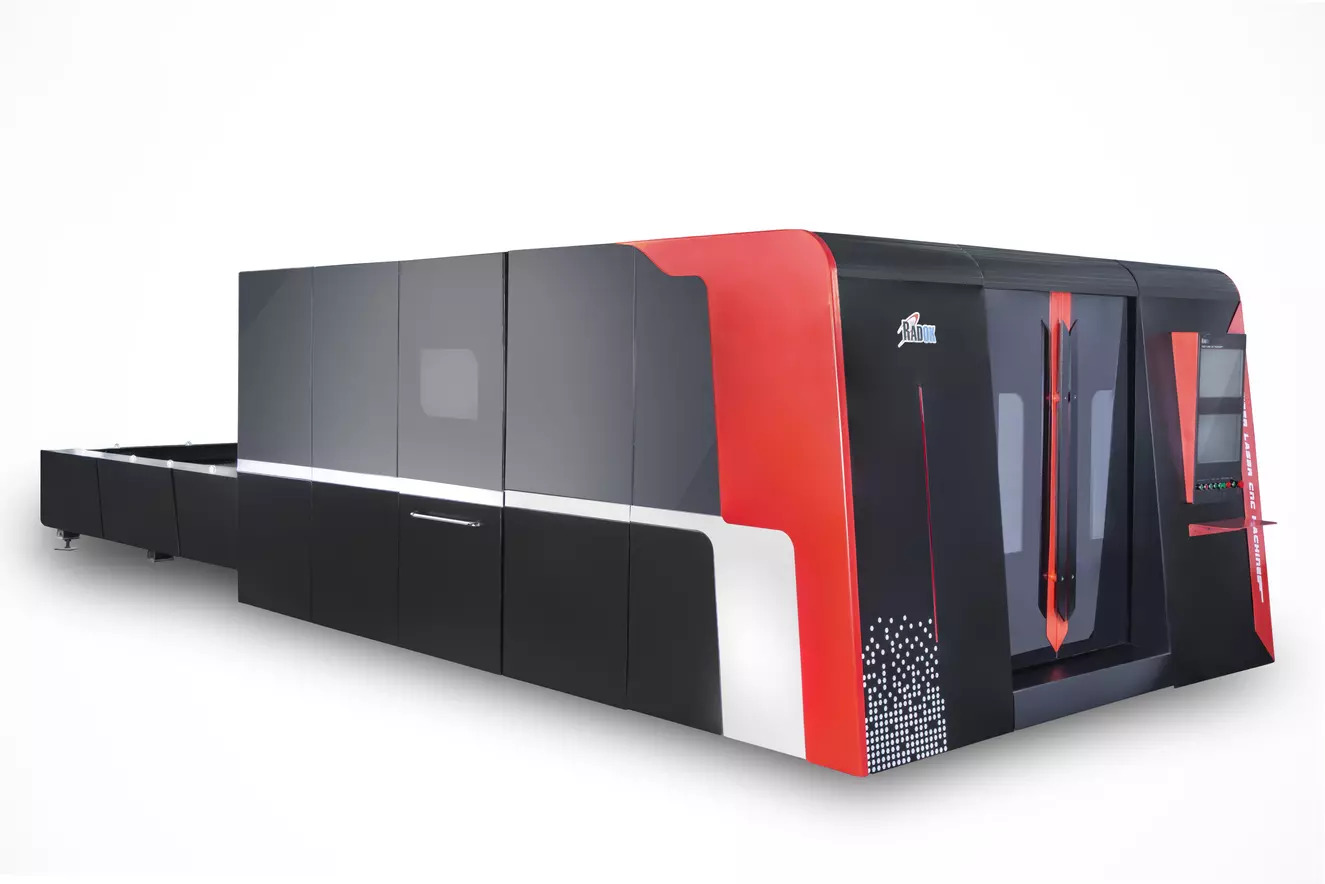

FIBER LASER CNC

.jpg)

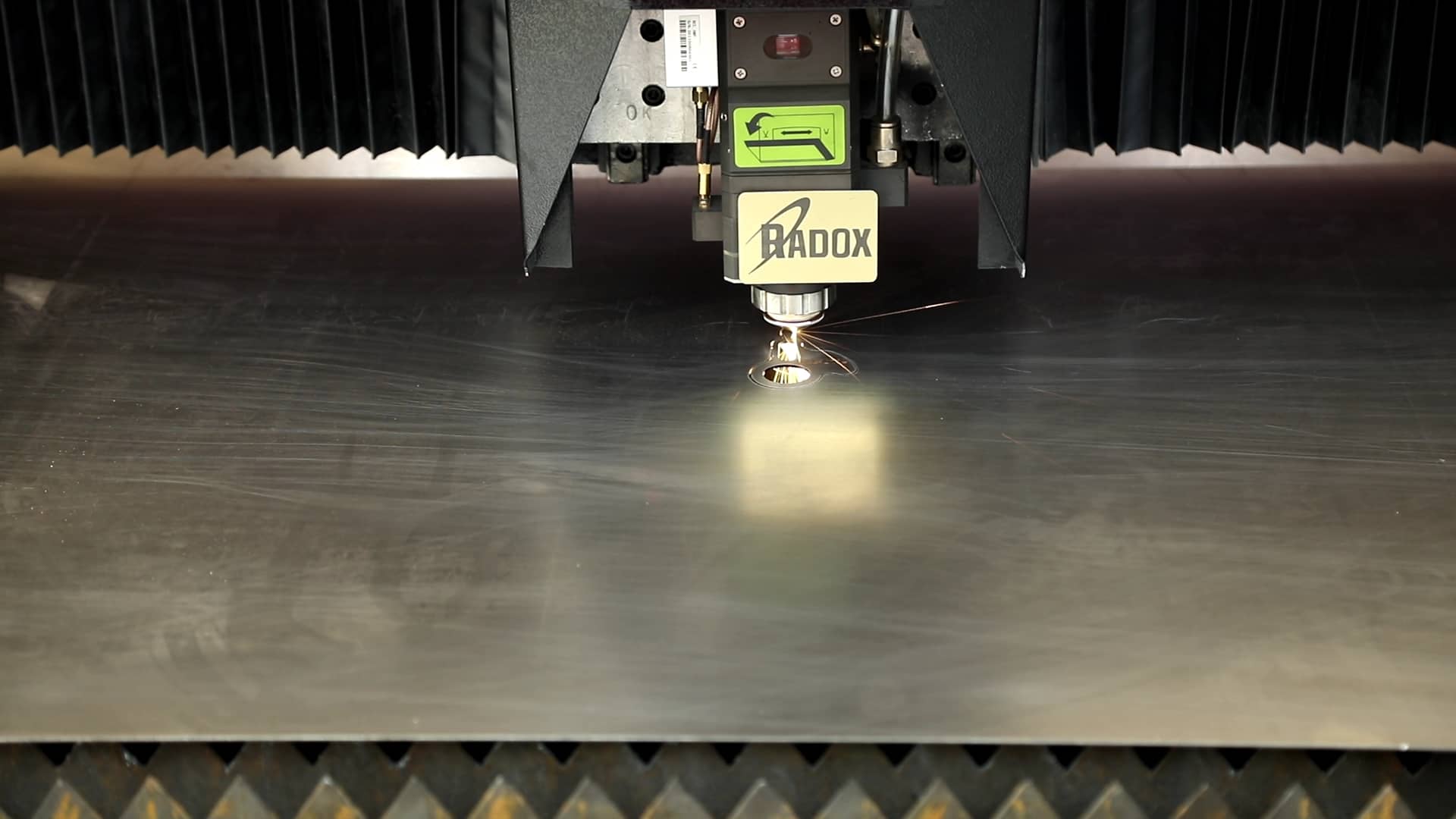

Laser cutting is a thermal cutting process for metal sheets. The laser beam is made by a laser resonator, a transport fiber or mirror at the cutting head of the device, where a lens focuses it with a very high power at a very small diameter. This focused laser beam meets the metal sheet and melts it.

Radox CNC laser cutting machine advantages:

Radox CNC laser cutting machines are equipped with the most advanced and accurate American and German parts.

Short delivery time

Low price and high quality

Special discounts for faithful customers

The largest CNC cutting machines manufacturer in Iran. It has a central site with an area of more than 60,000 square meters and complex of halls over 12,000 square meters

Laser CNC cutting capability

Able to cut all kinds of iron, steel, aluminum and copper sheets for a sheet thickness of 0.2 mm to 20 mm with an accuracy of 0.1 mm

Important points for CNC laser cutting

Steel

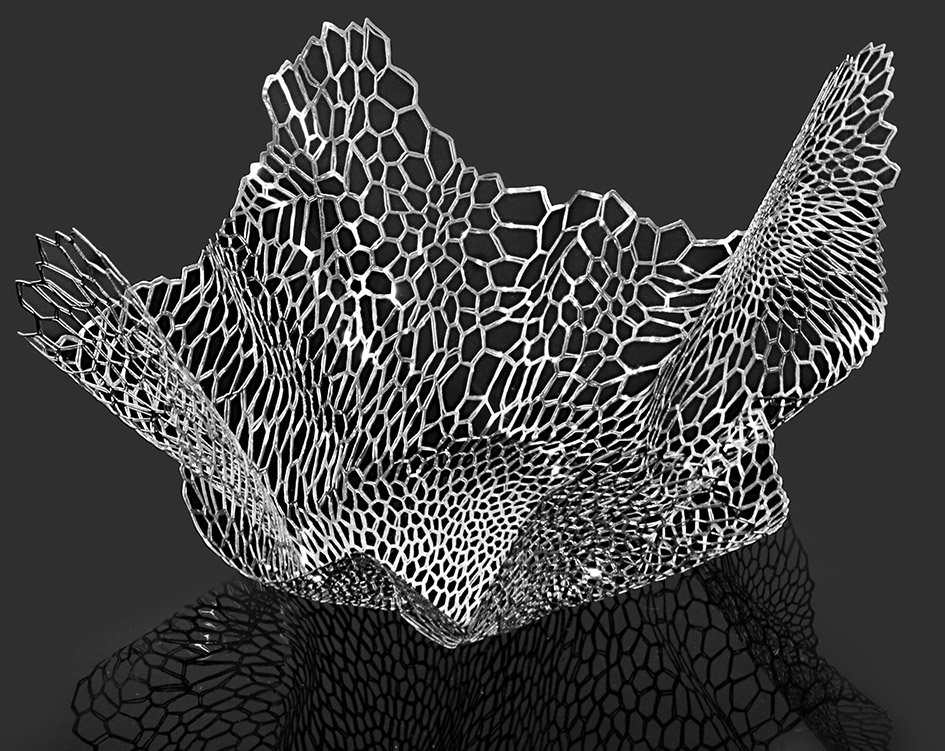

Conical angle: means the change in the diameter of the hole in the thickness of the cut.

Fins production: Definitely, the lower the plexus produced after cutting, the better the final quality and the less the need for a secondary machining process.

Kerf: In fact, Kerf defines the smallest radius that can be cut, which depends on the thickness of the sheet and should be considered in the design.

For example, very sharp corners should have a minimum r equivalent to a ridge. Also, the minimum holes that can be made in metal sheets depend on the thickness of the sheet. Obviously, the smaller the device, the more complex the contours and the smaller the thicker ribs.

Cutting speed: Much depends on the capabilities of the device and the power of the laser beam. The higher the power of the device, the higher the cutting speed will be.

Surface smoothing: One of the most important parameters in surface smoothing and non-oxidation cutting is that it is created by combining different technologies and precise adjustment of control parameters such as gas type, gas pressure, cutting speed and laser power adjustment.

ELEGANT

RADOX CNC fiber laser cutting machines are equipped with the most advanced and powerful international laser sources, and this combination creates very high quality cuts and unparalleled precision on a variety of metal materials. The very high technology used in RADOX laser fiber CNC cutting machines reduces the current cutting costs and the most competitive laser cutting method can be provided.

The new technology used in RADOX fiber laser makes it possible to cut all kinds of non-ferrous(colored) metals, while with the old technology, CO2 lasers it was not possible. Laser sources can be supplied in all capacities from low capacities to 12000W and can be installed on all types of CNCs.

EXTRA OPTION

Table changer & protection covers

ELEGANT

5 year CNC warranty. After sales service 15 years

Contact the company's experts

TLE:+98212776(INTERNAL 151, 152)